We offer everything needed for a space mission, including integration and testing of satellites and Earth-orbiting payloads.

Our facilities

Need for specific tests? We know where to do them

Assembly Integration and Test (AIT)

For this our headquarters are equipped with:

- A Clean Room with ISO 5 level (class 100) cleaning standards to better test all the optical and electronic instruments that will be key parts of our satellite systems. The Clean Room also allows us to store, integrate and test materials in accordance with our Quality Assurance-Product Assurance processes, and EX9100 and ECSS standards.

- A Thermo Vacuum Chamber inside the Clean Room, where we perform thermal tests in compliance with European space standards. The Thermal Vacuum Chamber allows us to reproduce an environment similar to space.

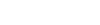

Protolab

The protolab allows us to manufacture in-house important mechanical and electronic components that are included in our systems and Ground Support Equipment. The laboratory is fitted out with machinery for mechanical processing, such as numerical control machines, and stations for the production of electronic boards.

Mission Control Centre (MCC)

We train astronauts and ground personnel, so that missions and experiments in orbit can be prepared in the best possible fashion.

In our MCC (Mission Control Centre) we have all the hardware and software necessary to connect directly with NASA and ESA channels, so as to acquire video, audio and telemetry in real time, supporting the astronauts on board the ISS.

We plan operations in real time by synchronising with NASA’s Johnson Space Centre in Houston and monitor the missions of our satellites in direct connection with NASA’s deep space network.

Thermal Lab

Our laboratory is fitted out to perform the thermal tests that allow us to do in-house the tests needed for the prototyping, production and verification phases of two-phase systems, such as heat pipes. The laboratory is also equipped with test instruments to verify the operation and performance of thermal devices and a filling system designed by us, which enables us to fill the heat pipes with working fluid, respecting the severest parameters.